How to Replace Needle on Record Player: Quick Guide for Turntable Maintenance

Replacing the needle on a record player is an essential skill for vinyl enthusiasts. A worn or damaged needle can diminish sound quality and potentially harm records. The process involves carefully removing the old needle and installing a new one that matches the cartridge model.

Regular maintenance of a turntable’s components ensures optimal audio performance. Needle replacement is a straightforward task that most users can perform at home with basic tools. This guide will walk through the steps to replace a record player needle, helping listeners preserve their vinyl collections and enjoy high-quality sound.

Proper needle care extends the life of both the stylus and records. Knowing when and how to replace a needle empowers music fans to take control of their listening experience. With the right approach, changing a turntable needle becomes a simple part of routine upkeep for any record player setup.

Understanding Record Player Mechanics

Record players operate using a series of mechanical components working in harmony. The main parts include the platter, tonearm, cartridge, and needle (stylus).

The platter is a circular platform that rotates the record. It’s driven by a motor, typically through a belt or direct drive system.

Mounted on a pivot, the tonearm allows the cartridge to move across the record’s surface. It’s carefully balanced to apply the right amount of pressure on the vinyl.

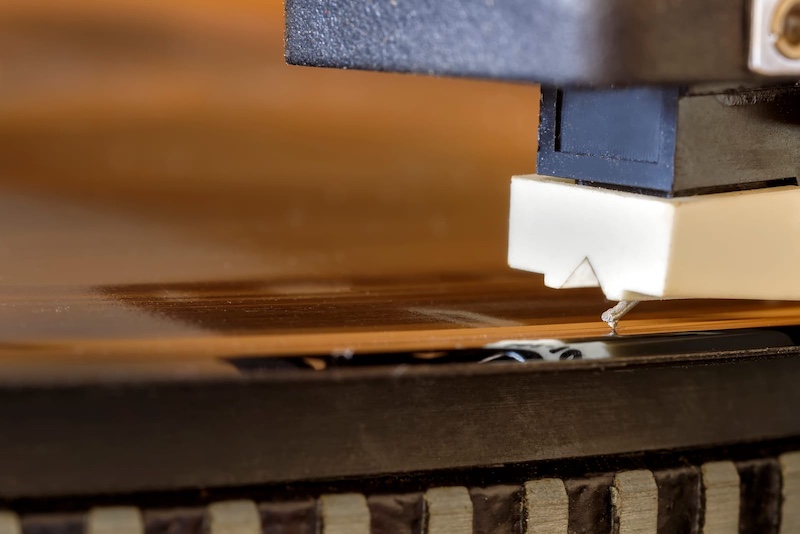

The cartridge houses the needle and converts physical vibrations into electrical signals. It’s attached to the end of the tonearm.

The needle, or stylus, is the small diamond-tipped component that sits in the record’s grooves. As it moves along these grooves, it picks up vibrations.

These vibrations travel up through the cartridge and tonearm. They’re then amplified and converted into the sound we hear through speakers.

Proper alignment of all these parts is crucial for optimal sound quality and to prevent damage to records. Regular maintenance and careful handling help ensure the longevity of both the player and vinyl collection.

Types of Needles and Styluses

Record player needles and styluses come in various types, each suited for different purposes and record materials. The most common are conical and elliptical styluses.

Conical styluses have a rounded tip and are generally more affordable. They offer good sound quality and are less prone to wear on vinyl records.

Elliptical styluses have an oval-shaped tip that provides better contact with record grooves. This results in improved sound detail and reduced distortion compared to conical styluses.

For high-end audio setups, there are more specialized options:

- Micro-ridge styluses: Offer superior sound quality but are more expensive

- Shibata styluses: Designed for quadraphonic records, they provide excellent high-frequency response

- Line contact styluses: Provide excellent tracking and reduced record wear

The material of the stylus tip also varies:

| Material | Characteristics |

|---|---|

| Diamond | Hardest, longest-lasting |

| Sapphire | Less durable, more affordable |

When choosing a stylus, consider factors such as budget, record collection value, and desired sound quality. Always match the stylus to your specific cartridge model for optimal performance.

Identifying the Need for Replacement

Regular inspection and assessment of your record player’s needle are crucial for maintaining optimal sound quality. Knowing when to replace the needle ensures your vinyl collection remains in pristine condition.

Visual Inspection

Examine the needle tip closely under good lighting. A magnifying glass can help spot signs of wear. Look for flattening, chipping, or bending of the needle tip. These indicate it’s time for a replacement.

Check the cantilever, the thin metal rod holding the needle. Any bending or misalignment suggests replacement is necessary. Dust and debris accumulation on the needle can also impact performance.

If you notice visible damage or excessive buildup, it’s best to replace the needle promptly.

Audio Quality Assessment

Listen carefully to your records. A worn needle often produces distorted sound. Pay attention to high frequencies, which may become harsh or brittle.

Excessive surface noise, like hissing or crackling, can indicate needle wear. Skipping or repeating grooves might also occur with a damaged needle.

Compare the sound quality between newer and older records. If older records sound significantly worse, the needle may be the culprit.

Track the needle’s usage. Many manufacturers recommend replacement after 800-1000 hours of play time.

Selecting the Correct Needle

Choosing the right needle for a record player is crucial for optimal sound quality and preserving vinyl records. The needle, also called a stylus, comes in various shapes and sizes to match different cartridges and turntable models.

To select the correct needle, first identify the cartridge brand and model on the turntable. This information is typically printed on the cartridge body or can be found in the turntable’s manual.

Once the cartridge is identified, research compatible needle options. Many manufacturers provide online databases or catalogs to help match needles with specific cartridges.

Consider the following factors when selecting a needle:

- Material (diamond, sapphire, or other)

- Tip shape (conical, elliptical, or other)

- Tracking force requirements

- Frequency response range

Higher-end needles often offer better sound quality and cause less wear on vinyl records. However, they may come with a higher price tag.

For vintage turntables, finding an exact replacement needle might be challenging. In such cases, consult with audio specialists or turntable restoration experts for suitable alternatives.

Always handle needles with care during installation. Improper handling can damage the delicate tip and affect sound quality.

Safety Precautions

Replacing a needle on a record player requires careful handling to protect both the equipment and oneself. Proper lighting is essential for this delicate task. Work in a well-lit area to clearly see the small components.

Always unplug the record player before starting any maintenance. This eliminates the risk of electric shock during the needle replacement process.

Wear protective eyewear to shield your eyes from potential debris or small parts. Magnifying glasses can also be helpful for seeing tiny details.

Handle the stylus and cartridge with extreme care. These components are fragile and easily damaged. Use clean, dry hands or wear lint-free gloves to avoid transferring oils or dirt.

Keep a clean workspace free of dust and debris. This prevents contamination of the stylus or turntable components.

Important tools:

- Small screwdriver

- Tweezers

- Soft brush for cleaning

Store old needles safely to prevent injury. Dispose of them properly according to local regulations for sharp objects.

If unsure about any step, consult the turntable’s manual or seek professional assistance. Improper handling can damage expensive equipment or compromise sound quality.

Preparation for Replacement

Proper preparation is key to successfully replacing a record player needle. Gathering the right tools and securing the turntable will ensure a smooth process.

Gathering Necessary Tools

To replace a record player needle, you’ll need specific tools:

- A small flathead screwdriver

- Needle-nose pliers

- A magnifying glass

- A soft, lint-free cloth

- Isopropyl alcohol

These items will help with the delicate task of removing the old needle and installing the new one.

It’s crucial to have the correct replacement needle for your specific cartridge model. Check the manufacturer’s specifications or consult a professional if unsure.

Securing the Record Player

Before beginning the replacement process, it’s essential to secure the record player:

- Unplug the turntable from the power source.

- Remove any records from the platter.

- Lock the tonearm in its rest position.

Place the turntable on a flat, stable surface with good lighting. Use a soft cloth to cover the platter, protecting it from potential scratches.

Carefully clean the area around the cartridge with isopropyl alcohol to remove any dust or debris. This step prevents contaminants from interfering with the new needle’s performance.

Removing the Old Needle

Locate the cartridge at the end of the tonearm. Carefully examine how it’s attached to identify the removal method.

For clip-on cartridges, gently pull the cartridge straight down to detach it. Be cautious not to damage the delicate wires.

Screw-mounted cartridges require a small screwdriver. Loosen the screws securing the cartridge, then carefully remove it.

Some models have a sliding mechanism. Push the cartridge forward to release it from the headshell.

Once the cartridge is free, locate the needle assembly. It’s usually held in place by a small clip or screw.

Use tweezers or needle-nose pliers to carefully grasp the old needle. Pull it straight out from the cartridge body.

If the needle is screwed in, use a small flathead screwdriver to loosen it. Turn counterclockwise until it comes free.

Place the old needle in a safe container for proper disposal. Avoid touching the needle tip to prevent injury.

Clean the cartridge body with a soft, lint-free cloth to remove any dust or debris before installing the new needle.

Installing the New Needle

Proper installation of a new needle is crucial for optimal sound quality and record preservation. This process involves precise alignment, careful attachment, and fine-tuning adjustments.

Aligning the Cartridge

Ensure the tonearm is level when the needle touches the record surface. Use a cartridge alignment protractor to position the cartridge correctly. Place the protractor on the turntable spindle and adjust the cartridge until it aligns with the grid lines.

Tighten the mounting screws gently to secure the cartridge in place. Double-check the alignment after tightening to ensure it hasn’t shifted.

Attaching the Needle

Handle the new needle with care, avoiding contact with the delicate tip. Gently slide the needle onto the cartridge, ensuring it clicks into place.

Some cartridges may require connecting small wires. Match the wire colors to the corresponding terminals on the cartridge. Use tweezers for precise placement if needed.

Final Adjustments

Set the tracking force according to the manufacturer’s recommendations. Use a tracking force gauge for accurate measurement. Adjust the anti-skate to match the tracking force.

Verify the vertical tracking angle (VTA) by ensuring the tonearm is parallel to the record surface when the needle is in the groove. Fine-tune the tonearm height if necessary.

Test the setup by playing a record and listening for any distortion or irregularities in sound quality. Make minor adjustments as needed for optimal performance.

Post-Installation Checklist

After replacing the needle on a record player, it’s crucial to perform a few final checks. This ensures optimal performance and prevents damage to records.

Visually inspect the needle alignment. The stylus should be perpendicular to the record surface when viewed from the front and side.

Check the tracking force using a stylus pressure gauge. Adjust if necessary to match the manufacturer’s recommended weight.

Verify anti-skate settings. This counteracts the tonearm’s tendency to move inward during playback.

Clean the new stylus with a soft brush before first use. This removes any debris that may have accumulated during installation.

Test the setup with an old or less valuable record. Listen for any abnormal sounds or distortion that could indicate issues.

Examine the tonearm’s movement across the record. It should glide smoothly without resistance.

Ensure proper cartridge connections. Verify that all wires are securely attached and not loose.

Double-check the tonearm height. Adjust if needed so it remains parallel to the record surface during playback.

By completing this checklist, users can feel confident their newly installed needle is ready for optimal performance.

Maintaining Your Record Player’s Needle

Regular maintenance of your record player’s needle is crucial for optimal sound quality and longevity of your vinyl collection. Dust and debris can accumulate on the needle, affecting its performance.

Clean the needle after each use with a soft brush designed for this purpose. Gently brush from back to front to remove any particles.

For a deeper clean, use a specialized cleaning solution made for record player needles. Apply a small amount to the brush and clean as described above.

Inspect the needle regularly for signs of wear or damage. Look for bends, chips, or excessive buildup that doesn’t come off with cleaning.

Replace the needle according to the manufacturer’s recommendations, typically every 1000 hours of play time. Some audiophiles prefer more frequent replacements for optimal sound quality.

Store your record player with the dust cover on when not in use to protect the needle from environmental contaminants.

Handle the tonearm and needle with care. Avoid dropping the needle onto the record or allowing it to drag across the surface.

Consider using a stylus force gauge to ensure the correct tracking force is applied, reducing unnecessary wear on both the needle and your records.

Troubleshooting Common Issues After Replacement

After replacing the needle on a record player, some issues may arise. Addressing these problems promptly ensures optimal sound quality and prevents damage to records.

Skipping or Jumping

If the needle skips across grooves, check the tracking force. Adjust it according to the cartridge manufacturer’s specifications. Ensure the tonearm is properly balanced and the anti-skate setting is correct.

Distorted Sound

Distortion can occur if the needle is not properly seated in the cartridge. Gently remove and reinsert the needle, making sure it’s fully secured. Verify that the needle is clean and free from debris.

No Sound

Check all connections between the cartridge and tonearm. Ensure the headshell is tightly fastened. Inspect the wires for any loose or broken connections.

Excessive Surface Noise

Clean the needle with a soft brush or specialized cleaning solution. Dust and debris can accumulate quickly, affecting sound quality. Regularly clean records to minimize noise.

Uneven Channel Balance

If one channel sounds louder than the other, check the cartridge alignment. Use an alignment protractor to ensure proper positioning. Verify that all wires are securely connected to the correct terminals.

Wobbling Playback

A wobbling sound can indicate an improperly seated stylus. Carefully remove and reinsert the needle. If the problem persists, the stylus may be bent or damaged and require replacement.

Regular maintenance and careful handling of the turntable components help prevent many common issues. If problems persist after troubleshooting, consult a professional technician for further assistance.